Through big data technology, we collect and analyze various data from automotive manufacturing processes in real-time, enabling real-time tracking and analysis of production conditions to improve production efficiency, product quality, and reduce manufacturing costs.

Application Scenarios

Smart Manufacturing

- Real-time Production Monitoring - Real-time monitoring of production line status and timely anomaly detection

- Predictive Equipment Maintenance - Equipment maintenance prediction based on operational data

- Quality Control Optimization - Quality control process optimization through data analysis

- Production Planning & Scheduling - Intelligent production planning and scheduling

Supply Chain Management

- Supplier Evaluation Analysis - Multi-dimensional supplier performance evaluation

- Inventory Optimization Management - Inventory level optimization based on demand forecasting

- Logistics Route Optimization - Optimize logistics delivery routes and costs

- Cost Control Analysis - Comprehensive cost analysis and control

Product Development

- User Requirement Analysis - Analyze user feedback and market demands

- Product Performance Optimization - Product design optimization based on usage data

- Test Data Analysis - In-depth analysis of product testing data

- Market Trend Prediction - Predict automotive market development trends

After-sales Service

- Vehicle Fault Diagnosis - Intelligent fault diagnosis and early warning

- Maintenance Prediction Analysis - Predict maintenance needs and costs

- Customer Satisfaction Analysis - Analyze customer satisfaction and improvement points

- Service Quality Enhancement - Continuous service quality improvement

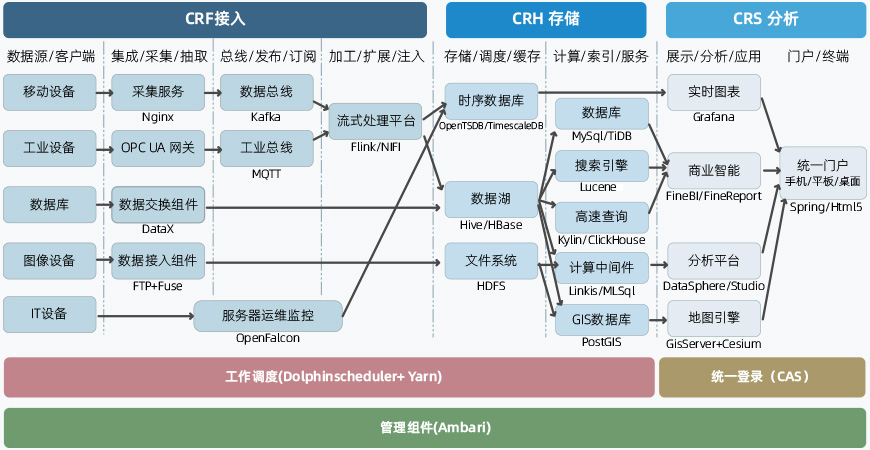

Technical Architecture

Data Collection Layer

- IoT Sensor Data - Production equipment sensor data collection

- Production System Data - MES, ERP system data integration

- Quality Inspection Data - Real-time quality inspection data collection

- External Data Sources - Market data, supplier data, etc.

Data Storage Layer

- HDFS Distributed Storage - Massive data storage

- HBase Real-time Database - Real-time data access

- Data Warehouse - Structured data storage

- Data Lake - Multi-format unified data storage

Data Processing Layer

- Kafka Message Queue - Real-time data stream processing

- Flink Stream Processing - Real-time data computation

- Spark Batch Processing - Large-scale batch data processing

- Machine Learning Platform - Intelligent algorithm applications

Application Service Layer

- Production Monitoring System - Real-time production status monitoring

- Quality Management System - Quality data analysis and management

- Predictive Maintenance System - Equipment maintenance prediction

- Decision Support System - Management decision support

Customer Benefits

Production Efficiency Improvement

- Equipment utilization increased by 15-25%

- Production cycle shortened by 10-20%

- Labor costs reduced by 20-30%

- Production planning accuracy improved to 95%

Quality Improvement

- Product qualification rate improved to 99.5% or above

- Customer complaint rate reduced by 50%

- Recall costs reduced by 80%

- Quality inspection efficiency improved by 3 times

Cost Control

- Raw material waste reduced by 15%

- Energy consumption reduced by 10-15%

- Maintenance costs reduced by 25%

- Inventory costs optimized by 20%

Success Case

Beijing Automotive Group

Through deploying StellerCore’s big data platform, Beijing Automotive achieved digital transformation of the entire production line and established a complete quality traceability system.

Implementation Results:

- Production efficiency improved by 22%

- Product quality significantly enhanced

- Customer satisfaction improved to 98%

- Annual cost savings of 20 million yuan

Project Highlights:

- Achieved full-process data traceability from raw materials to finished products

- Established intelligent quality warning system

- Optimized supply chain management processes

- Improved customer service response speed

Solution Features

Real-time Performance

- Millisecond-level data processing response

- Real-time production status monitoring

- Instant anomaly warning notifications

Intelligence

- AI-driven predictive analysis

- Intelligent decision support

- Automated process optimization

Scalability

- Support for rapid business growth

- Flexible architecture design

- Modular deployment approach

Security

- Enterprise-level security assurance

- Data encryption transmission

- Fine-grained permission management

Implementation Services

Consulting & Planning

- Business requirement analysis

- Technical architecture design

- Implementation roadmap planning

- ROI assessment analysis

Platform Deployment

- Infrastructure setup

- Platform software installation

- System integration configuration

- Data migration services

Training Support

- Technical personnel training

- Operator training

- Management training

- Continuous skill enhancement

Operation & Maintenance

- 7×24 technical support

- System monitoring and maintenance

- Performance optimization

- Rapid fault response